The automotive industry shifts towards composite material replacement, demanding specialized collision repair techniques. Advanced tools like cutters, bonding agents, and automated laying systems are essential for precise restoration. Innovations such as FRP systems, 3D printing, and smart materials expand applications in aerospace and car scratch repair. Strategic planning, training, standardized protocols, and advanced tools ensure efficient, high-quality composite repairs.

“In today’s advanced manufacturing landscape, the composite material replacement (CMR) revolution is gaining momentum. This article offers a comprehensive overview of tools and technologies transforming industries. From understanding the unique needs of CMR, including material properties and structural integrity, to exploring innovative solutions like automated cutting systems and advanced simulation software, we delve into the heart of this game-changing process. Additionally, practical implementation strategies ensure a successful transition, fostering efficiency and sustainability.”

- Understanding Composite Material Replacement Needs

- Exploring Advanced Tools and Technologies

- Implementational Strategies for Successful Transition

Understanding Composite Material Replacement Needs

In the realm of automotive craftsmanship, the demand for composite material replacement has been on the rise, driven by the increasing use of advanced composite materials in modern vehicles. This shift presents a unique challenge for collision repair services and car repair shops worldwide. As these lightweight, yet durable composites become more prevalent, the need for specialized tools and technologies to efficiently replace damaged parts without compromising structural integrity becomes crucial. Composite material replacement is not merely about fixing dents; it involves precise techniques to preserve the overall strength and performance of the vehicle, which is particularly important in collision damage repair processes.

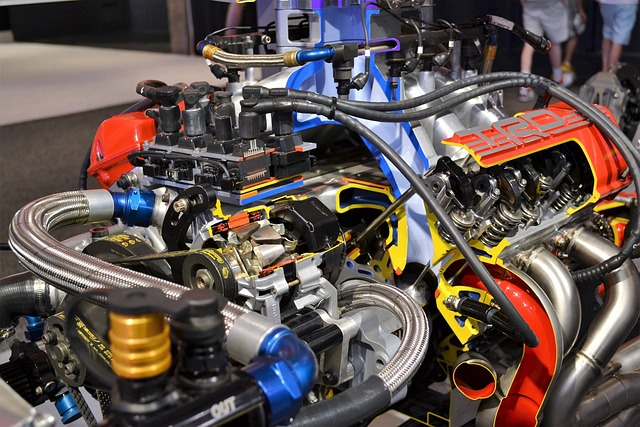

Understanding the specific requirements of composite material replacement is essential for any car repair shop aiming to offer top-tier services. This includes acquiring the right tools, such as specialized cutting equipment, bonding agents, and automated laying systems, to accurately replicate original designs and ensure structural integrity. By embracing innovative technology, collision repair professionals can enhance their capabilities, reduce repair times, and deliver high-quality outcomes for a growing range of composite material applications in modern automobiles.

Exploring Advanced Tools and Technologies

The world of composite material replacement is evolving rapidly, driven by advancements in tools and technologies that promise to revolutionize various industries. From automotive restoration to intricate frame straightening, professionals are now equipped with cutting-edge solutions for composite repair and customization. These innovations include advanced fiber-reinforced polymer (FRP) systems, which offer unparalleled strength-to-weight ratios and can be molded into complex shapes, making them ideal for a multitude of applications.

One notable area of exploration is the integration of digital design and manufacturing processes. 3D printing, in particular, has emerged as a game-changer, enabling precise creation of composite components, even those with intricate geometries previously challenging to reproduce. Additionally, the adoption of smart materials and sensors allows for more dynamic and adaptive structures, further expanding the possibilities for composite material replacement across sectors like aerospace, automotive restoration, and car scratch repair.

Implementational Strategies for Successful Transition

Implementing a shift towards composite material replacement in the automotive industry requires strategic planning and a systematic approach to ensure a successful transition. One key strategy is educating and training professionals, including mechanics and auto body repair technicians, on the new materials and their unique properties. This includes understanding how composites differ from traditional metals in terms of fabrication, repair, and maintenance. Specialized training programs can equip these workers with the necessary skills to handle composite material repairs efficiently.

Additionally, developing standardized protocols for composite material replacement in collision repair and automotive repair processes is vital. Standardized procedures ensure consistency and quality control, allowing for efficient adoption of new techniques. The use of advanced tools designed specifically for composite material handling further streamlines the transition. These tools can include specialized cutting equipment, adhesive applicators, and precision measurement devices tailored to meet the demands of composite repairs, enhancing overall efficiency in auto body repairs.

Composite material replacement tools and technologies have evolved significantly, offering diverse options to cater to various industry needs. By understanding specific requirements and implementing strategic approaches, organizations can successfully transition to composite materials, thereby enhancing structural efficiency and performance across multiple sectors. This overview highlights the transformative potential of these advanced tools in shaping the future of composite material application and fabrication.